With assembly complete, it's time to start painting. I've used mainly Inscribe craft acrylics with Vallejo acrylics for a few extra colours.

|

| Paints at the ready! |

My painting procedure is as follows:

1)

Base coat of Vallejo cold grey and inscribe taupe. This gives a nice

cement-coloured finish. For future buildings I'll probably just use

taupe with a few drops of black added, this gives a similarly grey-brown

colour. It doesn't matter if the ratios vary between batches, this

will add variation in colour which will be more realistic.

|

| Basic cement coat complete |

2)

Brick coat of Inscribe burnt umber. I use a wide, flat brush, wiped diagonally across the bricks

with the bristles almost parallel with the surface. This coats the bricks

well but leaves the recessed cement lines showing. Because this was a

quick trial run, I didn't take the usual care when plaster casting so

there are a number of bubbles in the bricks of the larger building which

are more noticeable once painted!

|

| Basic brick coat complete |

|

| Brick coat detail. |

3)

Pick out individual bricks in different shades by adding Inscribe

black, burnt sienna (terracotta) or caramel (yellow-brown) paint to the base colour. It's a random

scattering of bricks across the building. As always, click on the pictures if you want a close-up. Apologies for the variations in colour, these were photographed at different times under different light sources!

|

| Note wonky doorway on left! |

|

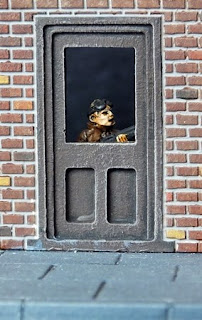

| Windows. |

|

| Click for close-up. |

|

| Click for close-up. |

The wonky doorway on the ridge roof building is even more noticeable when viewed next to the flat roof building!

|

| Wonky doorway even more noticeable here! |

This being just a quick proof-of-concept trial, I haven't worried about filling the gaps between the trimmed window sections.

|

| Trimmed window a better size for 15mm. |

|

| Another trimmed window - note the gaps! |

|

| Brick variation detail. |

4) Paint window frames white.

5)

I decided that one of the buildings would have a site number on the

side. I printed out the number in 72-point Impact font which is nice

and chunky.

|

| Font size selected to fit building. |

The number was carefully cut out with a craft knife to

create a stencil which was folded around the wall and secured with a

small piece of masking tape.

|

| Stencil carefully cut out. |

|

| Stencil in place, lined up with bricks. |

Originally it was going to be on the

smaller building but I realised that it would help hide the

aforementioned bubbles in the wall of the larger building!

|

| Changed my mind! Use it on this building instead. |

Vallejo

stonewall grey was stippled through the stencil followed by a further

stippling of white. This gives the effect of some of the paint being

paler and slightly worn away. The stippling was quite rough, the

incomplete coverage adding the effect of wear and tear.

|

| Stencil completed. |

The roof was painted in burnt umber with a few black tiles for variety.

|

| Roof base colour. |

A heavy drybrush of burnt sienna gives a nice terracotta finish. A few drops of caramel yellow was added for the final highlight.

|

| Terracotta drybrush. |

Part 4 will involve constructing a base for the buildings.

|

| Completed Building 19. |