For those who haven't encountered it before, Linka is a range of thin rubber moulds which can be used to cast interlocking panels to create walls, roofs etc. They come in a variety of styles including brick, stone and roof tile. There are moulds for plain wall sections, windows, doorways and more. I cast mine using Crystacal R casting plaster, the same as I use for my Hirst Arts dungeons.

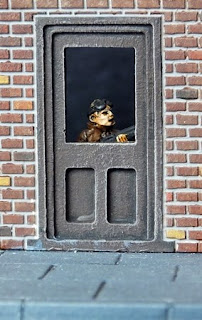

The scenery used in my Action Force photographs is built without modification (other than breaking and crumbling on the ruins) but the doorways look slightly too large when viewed more closely.

|

| Standard door |

1) plain brick sections;

2) a

basic assortment of door and window sections;

3) accessories (garden

walls, coping, angled walls etc);

Being

designed for OO/HO railways and 1/72 or 1/76 modelling, the standard

blocks look OK from a distance but the size discrepancy with 15mm

figures is much more obvious close-up. My initial experiments were just

to see how easy they were to stick together and how well they could be

painted. My next experiment is how well they can be adapted for 15mm

scale.

|

| Door and window |

|

| Door with window |

|

| Off cuts suitable for use as bund walls |

Windows

are more difficult - if you remove the lower 4 brick courses, the

bottom of the window is at ground level! While this might be desirable

in some instances, most of the time it will look rather odd so I've

removed the middle 4 brick courses. This requires a little more care

because both edges need to be quite accurate to ensure a clean fit of

the two halves and the centre section tends to snap rather easily. With

doors and plain wall sections, it doesn't matter if the base edge is a

little rough because you can hide it quite well by judicious application

of vegetation or other base texturing. Careful sanding is required,

though it's easy to remove too much, as I discovered.

In part 2 I'll move on to assembling a couple of trial buildings.

|

| Re-sized window and door |

No comments:

Post a Comment